Click here to download the instruction manual

Click here to download the settings

▌ Must-Read Before Purchase

Due to the low transmission depth of TH-HR, printed parts may easily fail to adhere to the build plate.

RESIONE does [not recommend] using the following types of machines:

1. 3D printers with automatic leveling features, such as AnyCubic Photon Mono M5s/M5s Pro/M7/M7 Pro, Phrozen Sonic Mighty Revo.

2. 3D printers with a tilting release mechanism, such as ELEGOO Saturn 4 Ultra/Mars 5 Ultra.

3. 3D printers with a non-conventional build platform locking mechanism, such as the CREALITY HALOT-MAGE series.

RESIONE [recommends] using the following printers: Phrozen Sonic Mini 8K/8KS, ELEGOO Saturn 3 Ultra.

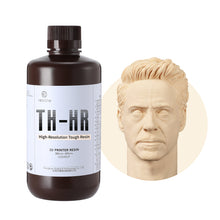

TH-HR, as a high-resolution, low-shrinkage, and high-precision tough material, is suitable for printing ultra-fine GK, head sculpts, mecha models, miniatures, car models, master mold for liquid silicone molding, and precision prototypes that require strength.

▌ Key Features

Combines Rigidity And Toughness

High Precision

High Resolution

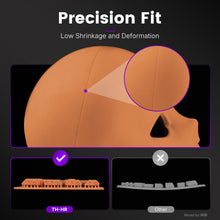

Low Shrinkage And Deformation

Matte Finish

Fine And Smooth Surface

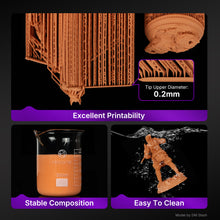

Stable Composition

Excellent Printability

Easy To Clean

▌ Descriptions

- Ultra-high precision and resolution

- Rigid and tough, Resistant to damage

- Low shrinkage, Low deformation

- Matt texture, Smooth surface

The printed parts feature a premium matte texture with non-translucent thin structures, making it easier to observe model details and imperfections. RESIONE recommends printing with a 0.02mm layer height, which ensures a fine and smooth surface, helping to reduce post-processing time.

- Premium user experience

The resin features stable composition, low sedimentation, and excellent moldability, significantly reducing printing failure rates. TH-HR resin supports the use of fine supports, which are easy to remove and leave minimal marks, simplifying post-processing. Printed parts can be easily and thoroughly cleaned, leaving the model's surface non-sticky after washing.

▌ Print Settings - 50um

TH-HR (Red clay) 50um

Operating Temp: 25~35℃/77~95℉

Layer Height: 0.05mm

Exposure Time: 3.2~4.8s

Bottom Exposure Time: 80~120s

Lifting Height:

LCD Screen size less than 8.9 inches: 6mm

LCD Screen size ≥8.9 inches: ≥10mm

Rest Time After Retract/Off times /Light-off Delay: ≥3s;

TH-HR (White clay) 50um

Operating Temp: 25~35℃/77~95℉

Layer Height: 0.05mm

Exposure Time: 2.8~4.2s

Bottom Exposure Time: 80~120s

Lifting Height:

LCD Screen size less than 8.9 inches: 6mm

LCD Screen size ≥8.9 inches: ≥10mm

Rest Time After Retract/Off times /Light-off Delay: ≥3s;

▌ Print Settings - 30um

TH-HR (Red clay) 20um

Operating Temp: 25~35℃/77~95℉

Layer Height: 0.02mm

Exposure Time: 1.8~2.7s

Bottom Exposure Time: 80~120s

Lifting Height:

LCD Screen size less than 8.9 inches: 6mm

LCD Screen size ≥8.9 inches: ≥10mm

Rest Time After Retract/Off times /Light-off Delay: ≥3s;

TH-HR (White clay) 20um

Operating Temp: 25~35℃/77~95℉

Layer Height: 0.02mm

Exposure Time: 1.6~2.4s

Bottom Exposure Time: 80~120s

Lifting Height:

LCD Screen size less than 8.9 inches: 6mm

LCD Screen size ≥8.9 inches: ≥10mm

Rest Time After Retract/Off times /Light-off Delay: ≥3s;

▌ Cleaning and Post-curing

- Cleaning tools: Hand washing

- Cleaning time: ≤5mins

- Cleaning liquid: 95% Ethanol or IPA

-

Post-curing method: For example, using the Anycubic Wash Plus curing and washing machine, cure the front and back of the printed object for 10 minutes each.

▌ Compatible 3D Printer

-

All series of Anycubic,Elegoo,Nova3d,Peopoly,Phrozen,Epax,Creality,Zortrax, BIQU, QIDI, UNIZ, Flashforge, Voxelab, Longer, Uniformation etc. UV 395-410nm LCD resin 3D printer

-

All series of Anycubic,Asiga, Elegoo, Solus series, Miicraft, Kudo3d, Flashforge,Makex,Shining etc. UV 385-410nm DLP resin 3D printer

▌ Material performance parameters

| METHOD | TH-HR White Clay | TH-HR Red Clay | |

| Viscosity(25℃)(mpa.s) | ASTM:D4212-10 | 768 | 821 |

| Liquid density(g/cm³) | ASTM:D4052-22 | 1.138 | 1.139 |

| Solid density(g/cm³) | ASTM:D792-20 | 1.204 | 1.21 |

| Shore Hardness(D) | ASTM:D2240-05 | 87 | 87 |

| Tensile Strength(MPa) | ASTM: D638-14 | 38.28 | 39.01 |

| Tensile Modulus(MPa) | ASTM: D638-14 | 1087 | 1172 |

| Elongation at Break | ASTM: D638-14 | 19% | 21% |

| Flexural Strength(MPa) | ASTM: D790-10 | 69.27 | 67.77 |

| Flexural Modulus(MPa) | ASTM: D790-10 | 1983 | 2026 |

| Notched IZOD(J/m) | ASTM:D256-10 | 20.1 | 21.92 |

| Water Absorption(24hr) | ASTM:D570-22 | 1.22% | 1.19% |