https://cdn.shopify.com/s/files/1/0464/1033/4360/files/HT100_resin_instruction.pdf?v=1641Take a look at the upgraded version of K resin: K+

Click here to download the instruction manual

Click here to download the settings

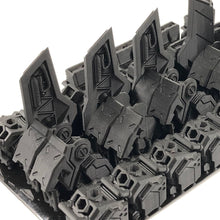

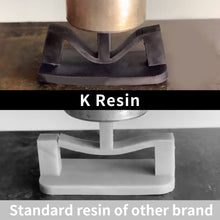

K resin is known for its excellent toughness and rigidity. This black material is not prone to overexposure under strong light sources, ensuring accurate size and sharp details. The mechanical properties of the printed parts are comparable to tough thermoplastics, allowing holes to be drilled, screws to inserted, and other high stress modifications, making it ideal for producing functional parts that will experience long term static load, transient stress or strain, but it is not suitable for underwater applications.

▌ Descriptions

- Mixed with F69/F39/F39T

- Good toughness and rigidity

- Precise size and sharp details

- Black color is high in saturation

- High-quality raw materials

▌ Reviews

- Youtube:ももジイChannel

- Impresion3daily

- Youtube: 3D-MPL

- Youtube: Тестирование фотополимерной смолы RESIONE K--By Федор Бихе

▌ Applications

- Functional parts

- Snap-fit designs

- Jigs and fixtures

-

Assembly parts

- Protective shell

- Miniatures

- Toy figures

▌ Compatible 3D Printer

-

All series of Anycubic,Elegoo,Nova3d,Peopoly,Phrozen,Epax,Creality,Zortrax, BIQU, QIDI, UNIZ, Flashforge, Voxelab, Longer, Uniformation etc. UV 395-410nm LCD resin 3D printer

-

All series of Anycubic,Asiga, Solus series, Miicraft, Kudo3d, Flashforge,Makex,Shining etc. UV 385-410nm DLP resin 3D printer

▌ Material performance parameters

| METHOD | DATA | |

| Viscosity(25℃)(mpa.s) | ASTM:D4212-10 | 335 |

| Liquid density(g/cm³) | ASTM:D4052-22 | 1.122 |

| Solid density(g/cm³) | ASTM:D792-20 | 1.197 |

| Shore Hardness(D) | ASTM:D2240-05 | 83 |

| Tensile Strength(MPa) | ASTM: D638-14 | 45 |

| Tensile Modulus(MPa) | ASTM: D638-14 | 1512 |

| Elongation at Break | ASTM: D638-14 | 18.60% |

| Flexural Strength(MPa) | ASTM: D790-10 | 67.2 |

| Flexural Modulus(MPa) | ASTM: D790-10 | 2080 |

| Notched IZOD(J/m) | ASTM:D256-10 | 33.4 |

| Water Absorption(24hr) | ASTM:D570-22 | 1.02% |

You may also like

-

Anti-impact Resin Durable Nylon-like (1kg)

![]()

- Regular price

- $59.00

- Sale price

- $59.00

- Regular price

-

$65.00 - Unit price

- per

Sold out -

K+ Black Tough ABS-Like Resin (1kg)

![]()

- Regular price

- $49.00

- Sale price

- $49.00

- Regular price

-

$55.00 - Unit price

- per

Sold out -

M68 White Tough ABS Like Non-yellowing 3D Printer Resin (1kg)

![]()

- Regular price

- $49.00

- Sale price

- $49.00

- Regular price

-

$55.00 - Unit price

- per

Sold out -

M58 Gray Tough ABS Like 3D Printer Resin (1kg)

![]()

- Regular price

- $49.00

- Sale price

- $49.00

- Regular price

-

$55.00 - Unit price

- per

Sold out