Click here to download the instruction manual

Click here to download the settings

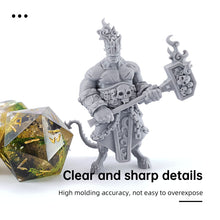

M58 is a gray material known for its rigidity and toughness. The mechanical properties of the printed parts are comparable to tough thermoplastics, allowing holes to be drilled, screws to inserted, and other high stress modifications, making it ideal for producing functional parts that will experience long term static load, transient stress or strain, but it is not suitable for underwater applications. This 3D printer resin boasts high molding precision, wear resistance, and a smooth surface that preserves fine details from the original 3D file, so it’s also well-suited for producing miniatures and action figures.

▌ Descriptions

- Sturdy like ABS

- Wear-resistant and scratch-resistant

- Clear and sharp details

- High-quality raw materials

- Mixed with F69/F39/F39T

▌ Reviews

- Youtube: ガンプラ改造全塗装:HG ナイチンゲール vol.3[HG NIGHTINGALE custom build vol.3][3Dプリンター][光造形][魔改造]--七式ガンプラ部

- Youtube: ガンプラ改造全塗装:HG ナイチンゲール vol.4[HG NIGHTINGALE custom build vol.4][3Dプリンター][光造形]--七式ガンプラ部

- Youtube:FOB Scale Modellbau-Resione M58&M68 VS Anycubic ABS-LIKE resin

- Youtube: How I mix Resins for my Action Figure 3D Prints | Azrach Toys

-

Youtube: べにやのVlog

- Youtube: M58 & Anti Impact--Nathan Kozuch

▌ Applications

- Action figures

-

Miniatures

- GK

- Functional parts

-

Assembly parts

-

Jigs and fixtures

- Snap-fit designs

▌ Compatible 3D Printer

-

All series of Anycubic,Elegoo,Nova3d,Peopoly,Phrozen,Epax,Creality,Zortrax, BIQU, QIDI, UNIZ, Flashforge, Voxelab, Longer, Uniformation etc. UV 395-410nm LCD resin 3D printer

-

All series of Anycubic,Asiga, Solus series, Miicraft, Kudo3d, Flashforge,Makex,Shining etc. UV 385-410nm DLP resin 3D printer

▌ Material performance parameters

| METHOD | DATA | |

| Viscosity(25℃)(mpa.s) | ASTM:D4212-10 | 389 |

| Liquid density(g/cm³) | ASTM:D4052-22 | 1.12 |

| Solid density(g/cm³) | ASTM:D792-20 | 1.2 |

| Shore Hardness(D) | ASTM:D2240-05 | 88 |

| Tensile Strength(MPa) | ASTM: D638-14 | 52.3 |

| Tensile Modulus(MPa) | ASTM: D638-14 | 1820 |

| Elongation at Break | ASTM: D638-14 | 22.55% |

| Flexural Strength(MPa) | ASTM: D790-10 | 71.36 |

| Flexural Modulus(MPa) | ASTM: D790-10 | 2129 |

| Notched IZOD(J/m) | ASTM:D256-10 | 43.8 |

| Water Absorption(24hr) | ASTM:D570-22 | 1.25% |