A stable and reliable standard Pro resin, with printed parts featuring low shrinkage deformation, high detail precision, and a matte, premium texture.

▌ Key Features

Low shrinkage deformation, Matte finish, Sharp details, Easy to use, Stable, Fast post-processing, Low water absorption

▌ Descriptions

- Low Shrinkage and Stable Printing

- Matte finish that showcases intricate details

- Easy Cleaning

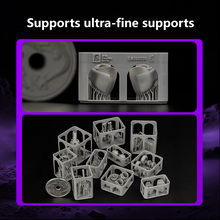

- Support for Ultra-Fine Supports

The clever formulation of SP64 and its good strength during the printing process allow users to set Tip Upper Diameter of 0.1 mm or 0.15 mm for small-scale or lightweight models. Such supports are easier to remove and sand, speeding up post-processing.

- Wide Compatibility and User-Friendly Operation

This resin is compatible with the parameter settings of mainstream LCD/MSLA/DLP 3D printers, allowing users to skip complicated adjustments, making it easy for beginners to get started quickly.

▌ Attention

- Although this material has matte properties, the matte effect also depends on many factors such as the printer and the angle at which the model is placed, so the final print may be semi-matte.

- If the post-curing time is too long, it can cause warping of the printed parts and make them become brittle. If you need the printed parts to maintain certain toughness, please minimize the post-curing time as much as possible. Non-hollow miniatures may even be left without post-curing.

- Immediately after post-curing, the printed parts is fragile. It is not recommended to apply force to the prints. It is advisable to wait for a period of time for the prints to cool naturally to release internal stresses and restore its intended mechanical properties.

▌ Print Settings - Light peach

- Operating Temp: 25~35℃/77~95℉

- Layer Height: 0.05mm

- Exposure Time: 2~3s

- Bottom Exposure Time: 40~50s

Lifting Height:

- LCD Screen size less than 8.9 inches: 6mm

- LCD Screen size ≥8.9 inches: ≥9mm

- Rest Time After Retract/Off times /Light-off Delay: ≥3s

▌ Print Settings - Medium gray, Blue-gray, Black

- Operating Temp: 25~35℃/77~95℉

- Layer Height: 0.05mm

- Exposure Time: 2.4~3.6s

- Bottom Exposure Time: 50~60s

Lifting Height:

- LCD Screen size less than 8.9 inches: 6mm

- LCD Screen size ≥8.9 inches: ≥9mm

- Rest Time After Retract/Off times /Light-off Delay: ≥3s

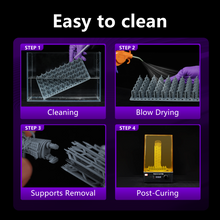

▌ Cleaning and Post-curing

- Cleaning tools: Hand washing

- Cleaning time: ≤5mins

- Cleaning liquid: 95% Ethanol or IPA

-

Post-curing method: For example, using the Anycubic Wash Plus curing and washing machine, cure the front and back of the printed object for 0~3 minutes each.

▌ Compatible 3D Printer

-

All series of Anycubic,Elegoo,Nova3d,Peopoly,Phrozen,Epax,Creality,Zortrax, BIQU, QIDI, UNIZ, Flashforge, Voxelab, Longer, Uniformation etc. UV 395-410nm LCD resin 3D printer

-

All series of Anycubic,Asiga, Elegoo, Solus series, Miicraft, Kudo3d, Flashforge,Makex,Shining etc. UV 385-410nm DLP resin 3D printer

▌ Material performance parameters

| METHOD | SP64 | |

| Viscosity(25℃)(mpa.s) | ASTM:D4212-10 | 495 |

| Liquid density(g/cm³) | ASTM:D4052-22 | 1.105 |

| Solid density(g/cm³) | ASTM:D792-20 | 1.24 |

| Shore Hardness(D) | ASTM:D2240-05 | 95 |

| Tensile Strength(MPa) | ASTM: D638-14 | 49.91 |

| Tensile Modulus(MPa) | ASTM: D638-14 | 1667 |

| Elongation at Break | ASTM: D638-14 | 5.99% |

| Flexural Strength(MPa) | ASTM: D790-10 | 82.9 |

| Flexural Modulus(MPa) | ASTM: D790-10 | 2718 |

| Notched IZOD(J/m) | ASTM:D256-10 | 14.18 |

| Water Absorption(24hr) | ASTM:D570-22 | 0.61% |