Click here to download the instruction manual

Dear Valued Customer,

Starting from September 9, 2024, the product previously known as WATER FAIRY will officially be renamed as WW123. For future orders, both the old and new packaging may be shipped randomly.

Please note that the product formulation has not changed, only the name has been updated.

We apologize for any inconvenience this may cause and thank you for your continued support!

WW123(Water Fairy) is a water washable resin that is almost not picky about users, 3D printers, 3D data, and work environments. It can be directly cleaned with water, with almost odorless raw materials, and simple and convenient post-treatment without discomfort. The fluidity of Water Fairy(WW123) is close to that of water, which allows it to adapt to larger printing sizes and high-speed printing modes. Users can directly use the parameters of the standard resin of each printer model for printing, which is very friendly to beginners. In addition, high precision, non-cracking, and moisture resistance are also excellent characteristics that it has to mention. Moreover, the product has a variety of color options, making it expected to become the "EVERYDAY RESIN" for many users.

▌ Reviews

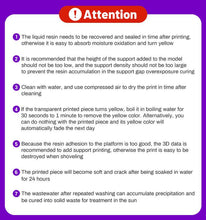

▌ Attention

-

Liquid resin needs to be promptly recycled and sealed for storage after printing, otherwise it may easily absorb moisture, oxidize, and turn yellow (only for crystal clear color)

-

It is recommended that the height of the support added to the model should not be too low, and the support density should not be too large to prevent the resin accumulation in the support gap overexposure curing

-

Clean with water, and use compressed air to dry the print in time after cleaning

-

If the transparent printed piece turns yellow, boil it in boiling water for 30 seconds to 1 minute to remove the yellow color. Alternatively, you can do nothing with the printed piece and its yellow color will automatically fade the next day

-

Because the resin adhesion to the platform is too good, the 3D data is recommended to add support printing, otherwise the print is easy to be destroyed when shoveling

-

The printed piece will become soft and crack after being soaked in water for 24 hours

- The wastewater after repeated washing can accumulate precipitation and be cured into solid waste for treatment in the sun

▌ The difference between WW123(Water Fairy) and W90B

- Colors and color options are different

- WW123(Water Fairy) has lower viscosity

- Easier to be washed clean with water

- More suitable for beginners to use

- Moisture resistant, non cracking

▌ Descriptions

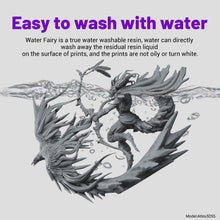

- Easy to wash with water

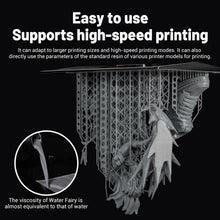

- Easy to use, supports high-speed printing

- Almost odorless, convenient to use

- High precision, sharp details

This resin is not easy to overexpose, nor is it easy to accumulate material in gaps in support and pores in the models. It can accurately present the fine details of 3D data such as grooves, textures, hair, holes, and protrusions. Details remain sharp even after the printed part has been painted, pen-coated or after silica gel moulding.

- Non-cracking, moisture resistance

The strength of the printed piece is good. After appropriate post curing, it can not crack due to changes in indoor temperature and humidity. However, do not expose the printed piece to water for a long time.

▌ Print Settings

- Operating Temp: 20~35℃/68~95℉

- Layer Height: 0.05mm

- Exposure Time: 2~3s

- Bottom Exposure Time: 30~60s

- Lifting Height:

LCD Screen size less than 8.9 inches: 5mm

LCD Screen size ≥8.9 inches: ≥8mm - Rest Time After Retract/Off times /Light-off Delay: ≥1s

▌ Cleaning and Post-curing

- Cleaning time: ≤3mins

- Cleaning liquid: water

- Post-curing light source: 385-405nm UV(40W)

- Post-curing time: 2~5min

▌ Compatible 3D Printer

-

All series of Anycubic,Elegoo,Nova3d,Peopoly,Phrozen,Epax,Creality,Zortrax, BIQU, QIDI, UNIZ, Flashforge, Voxelab, Longer, Uniformation etc. UV 395-410nm LCD resin 3D printer

-

All series of Anycubic,Asiga, Elegoo, Solus series, Miicraft, Kudo3d, Flashforge,Makex,Shining etc. UV 385-410nm DLP resin 3D printer

▌ Material performance parameters

| METHOD | WW123 | |

| Viscosity(25℃)(mpa.s) | ASTM:D4212-10 | 12 |

| Liquid density(g/cm³) | ASTM:D4052-22 | 1.092 |

| Solid density(g/cm³) | ASTM:D792-20 | 1.2 |

| Shore Hardness(D) | ASTM:D2240-05 | 85 |

| Tensile Strength(MPa) | ASTM: D638-14 | 35 |

| Tensile Modulus(MPa) | ASTM: D638-14 | 1470 |

| Elongation at Break | ASTM: D638-14 | 9.00% |

| Flexural Strength(MPa) | ASTM: D790-10 | 64.65 |

| Flexural Modulus(MPa) | ASTM: D790-10 | 2007 |

| Notched IZOD(J/m) | ASTM:D256-10 | 23.4 |

| Water Absorption(24hr) | ASTM:D570-22 | 5.71% |